R&D [Research and Development Area]

Functional Materials

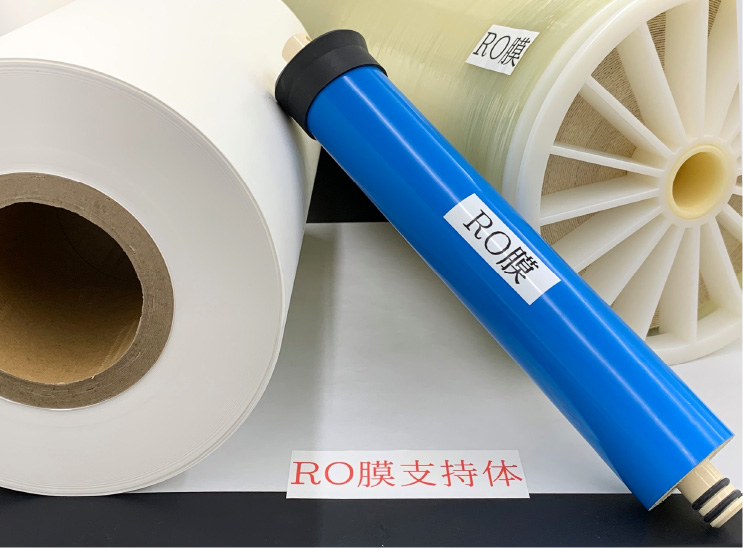

Membrane Supports

Using our paper-making technology for wet nonwoven fabrics, which is a fundamental technology we have developed over many years, we are working to develop membrane supports suitable for various fields such as food, pharmaceuticals, and industrial membranes, including water treatment membrane supports that contribute to achieving SDG Goal 6, which is to supply safe water throughout the world.

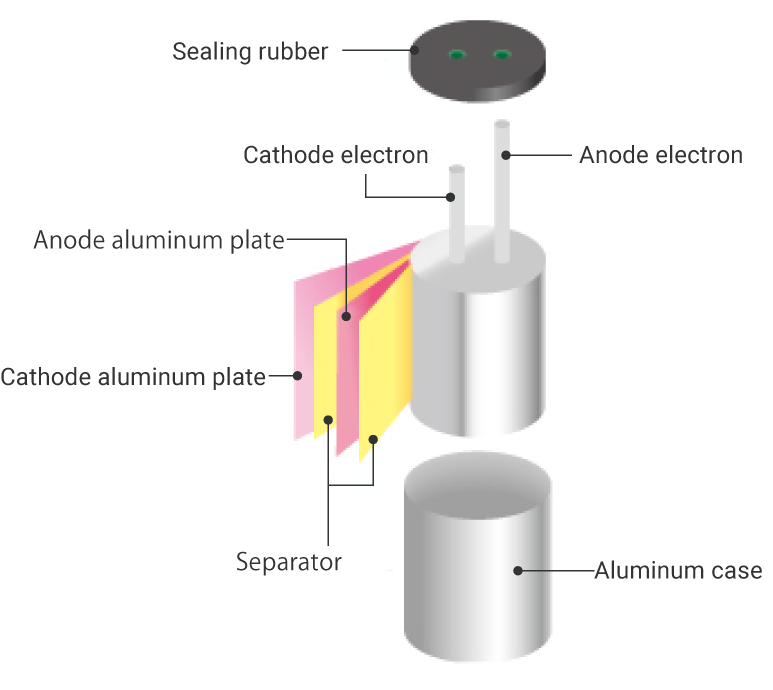

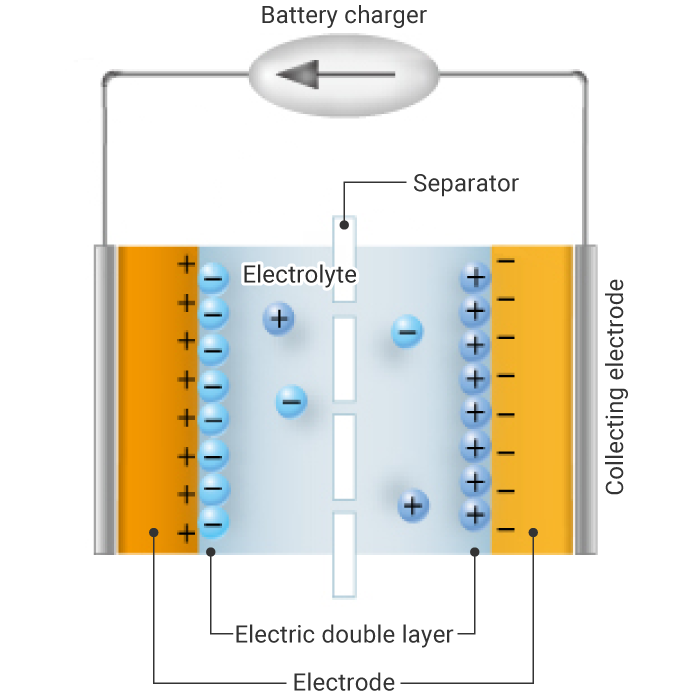

Separator

We are developing separators used in electronic components such as lithium-ion batteries, energy storage devices such as EDLCs (electric double layer capacitors), and high-performance electrolytic capacitors, which combine the contradictory properties of thinness and high strength by making full use of "paper-making technology" of wet nonwoven fabrics. In designing separators, we do not only rely on empirical rules of thumb, but also introduce scientific and theoretical methods using digital technology to achieve higher separator performance.

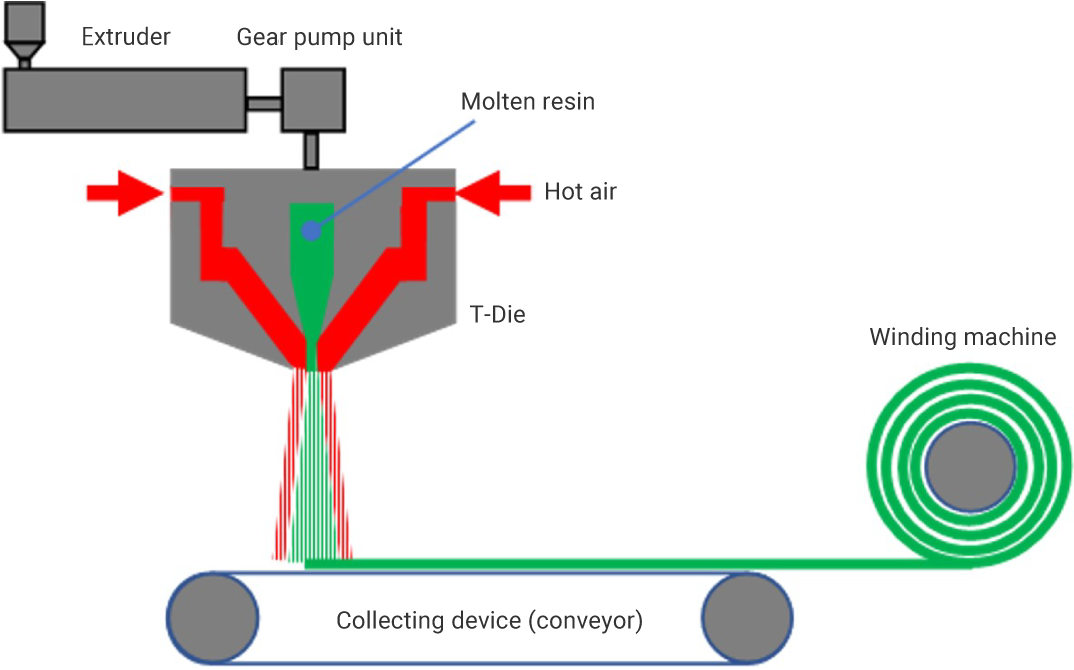

Melt-blown non-woven fabric

Melt-blown nonwovens are dry nonwoven fabrics made by forming sheets of thread-like thermoplastic resin extruded from a nozzle with a row of fine holes, blowing it away with high-speed hot air to form ultrafine fibers several microns in diameter, and collecting it directly on a collection device (conveyor). The manufacturing process is similar to that of cotton candy sold at fairs. Melt-blown nonwoven fabrics, in which ultrafine fibers form a dense network, are characterized by their air permeability and shielding properties. Familiar examples include non-woven masks and air filters, which have become necessities in the prevention of new coronavirus infection.

By adjusting raw materials and manufacturing conditions, we are working to develop functional nonwovens with features such as meltblown nonwovens made of ultrafine fibers, high-performance meltblown nonwovens that easily trap airborne particles and virus droplets such as PM2.5, and antibacterial and antiviral properties.

Super heat resistant sheet

By optimally combining the "paper-making technology" of wet nonwoven fabrics using inorganic fibers and the "coating technology" of inorganic pigment materials, we are developing super heat-resistant sheets with features such as heat resistance, heat insulation, and heat dissipation.

Super heat-resistant sheets can withstand burners of 1000°C or higher. We are also developing a wide range of products, from thin nonwoven fabric types to board types with thicknesses of 1 to 10 mm, for deployment in various fields such as construction materials and automobiles.