Sustainability [Actions for the Environment]

Raw Material Procurement

Basic approach to raw material procurement

Basic policy for purchasing materials

- 1. Impartiality and Fairness

- Mitsubishi Paper Mills treats its suppliers with decency and integrity, and treats them fairly and impartially in its transactions.

- 2. Sourcing optimal purchases

- For all purchases, including raw materials, auxiliary materials, fuel, and machinery, we comprehensively consider the quality, cost, delivery time, technological development capabilities, stable supply, and corporate stance (compliance with laws and regulations, severing ties with those affiliated with organized crime, protection of intellectual property rights, protection of human rights, consideration for the health and safety of workers, non-use of conflict minerals, security trade control initiatives, environmental considerations, etc.) to determine the most suitable business partners.

- 3. Partnership

- We aim to establish mutually beneficial business relationships with all of our suppliers, recognizing them as partners in providing competitive products.

Revised September 2015.

Our approach to timber procurement and products and the protection and development of forest resources

- Timber is sourced after ensuring that it is produced in compliance with local laws and regulations.

- Wood will not be procured from forests with high conservation value where which is being threatened.

- Wood that has been harvested in violation of human rights and the right to protect traditional practices will not be procured.

- Wood will not be sourced from genetically modified trees.

- Plantation trees and secondary forest timber with a clear history and environmental considerations, or recycled timber will be procured.

- Continue to procure wood (FSC® certified wood) from properly managed forests.

- Promote proper forest management and the spread of reliable forest certification systems through the active development and sale of FSC®-certified products.

- Appropriate information regarding the above initiatives will be disclosed in a timely manner.

Revised April 2015.

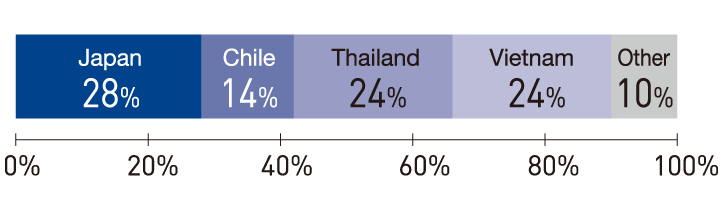

Raw Wood Procurement

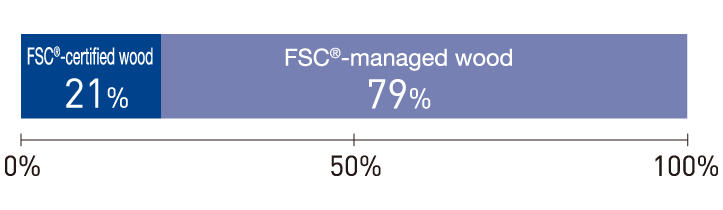

We have verified that all wood chips and wood pulp procured in FY 2022 came from forests that were legally and appropriately managed.

FSC®Forest Certification System

FSC® forest certification aims to improve the health of forests around the world by reviewing and certifying responsible forest management from economic, environmental and social perspectives, and labeling timber and wood products produced in those forests. In 2001, our Hachinohe Mill became the first paper mill in Japan to obtain CoC certification (certification for the management of processing and distribution processes), and began producing FSC®-certified paper. Since then, we have successively acquired CoC certification at our domestic factories and have expanded the variety of certified products. We have also been working to obtain FM certification for our domestic company-owned forests, and have obtained forest certification for our company-owned forests in Iwaizumi Town, Iwate Prefecture, Shichinohe Town, Aomori Prefecture, and Saigo Village, Fukushima Prefecture. In addition, in October 2017, the Vancouver Declaration on SDGs and FSC® Certification, which calls for increased support for the SDGs and FSC®, was announced at the FSC® General Assembly, and Mitsubishi Paper Mills stands in solidarity with the declaration, signing it along with 57 other companies in Japan and other countries.

Verification of legality and proper management

We have confirmed that all wood chips and wood pulp came from forests that were legally and appropriately managed, using one of the following methods:

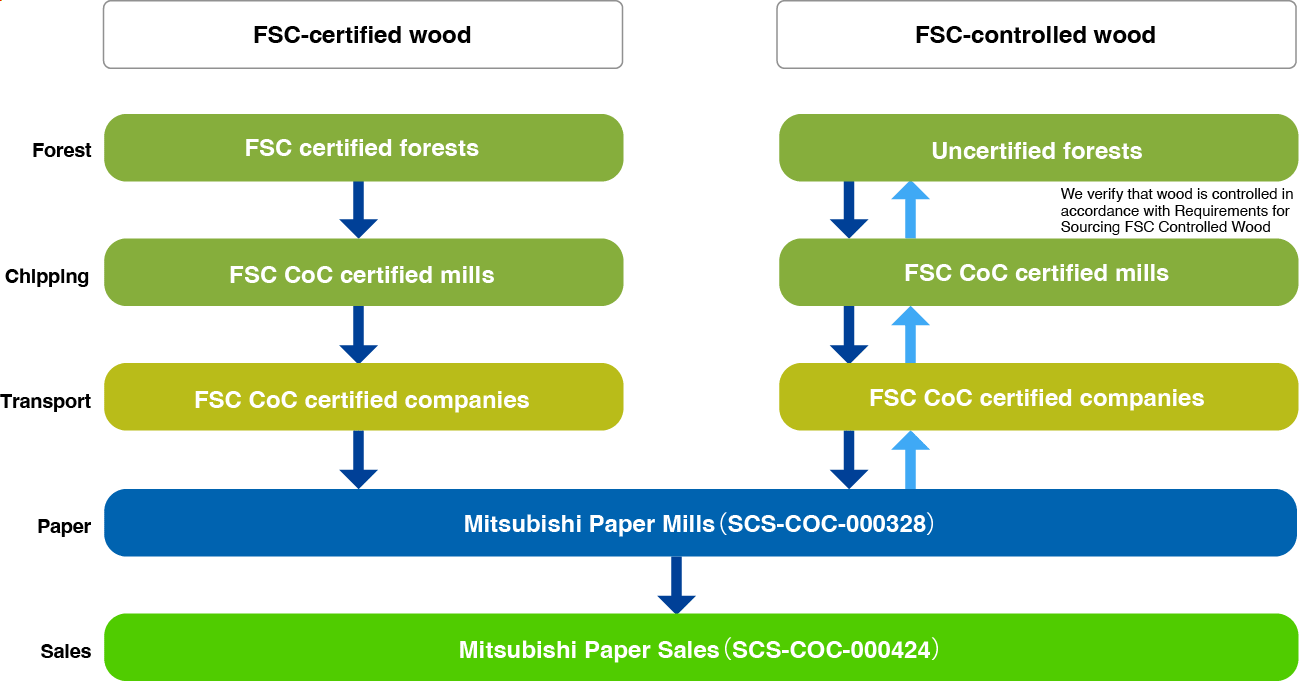

- Verification methods using forest certification and CoC certification systems (FSC®certified wood, FSC® controlled wood)

- Verification methods using the independent efforts of individual companies, etc.(controlled wood)

In 2, we verify that wood is controlled in accordance with the FSC® Requirements for Sourcing Controlled Wood (FSC®-STD-40-005). The verification methods that comply with this standard are as follows:

i. Collection of information concerning wood chips and pulp

- Understand the place of origin, wood type, forest management methods, etc. from traceability reports

- Confirmation of documentation certifying the place of origin (e.g. documents related to transport and sales)

- Regularly auditing suppliers and verifying document reliability

ii. Risk assessment (taking measures to mitigate risk when necessary)

- Assessing and verifying that place of origin of wood possesses a low risk with respect to (A) through (E) below.

A) Illegal logging

B) Violation of traditional and human rights

C) Threats to the high conservation value of forests

D) Conversion of natural forests to plantations or non-forest uses

E) Genetically modified trees

- Have the results of the risk assessment audited by an FSC® certification body

The flow of verification from forest to product is shown in the diagram below.

* FSC® controlled wood: wood that has been identified as low risk with regard to A) to E) according to the FSC® controlled wood standard and is recognised by FSC® certification bodies.

Compliance with the Clean Wood Act.

Our company uses the FSC® forest certification system to verify legality as required by the "Act on Promotion of Distribution and Use of Legally Harvested Timber, etc." (commonly known as the Clean Wood Act), which came into force on May 20, 2017. In addition, businesses that verify legality under this act (such as our company) can register with a third-party organization certified by the government, and we registered in March 2018.

Legal certification due diligence system manual

The Legal Certification Due Diligence System Manual has been developed in cooperation with the Japan Paper Association with the goal of minimising the risk of procuring illegally harvested wood products.