- HOME >

- Products & Services >

- ThermoRewrite >

- Mechanism

Mechanisms of ThermoRewrite

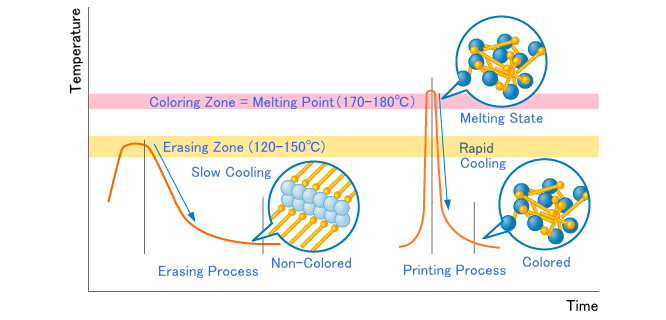

Process of printing and erasing

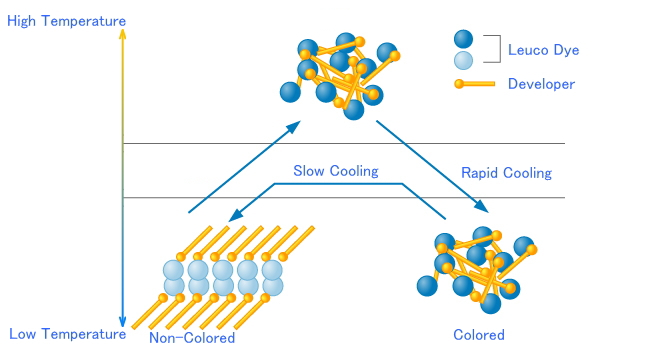

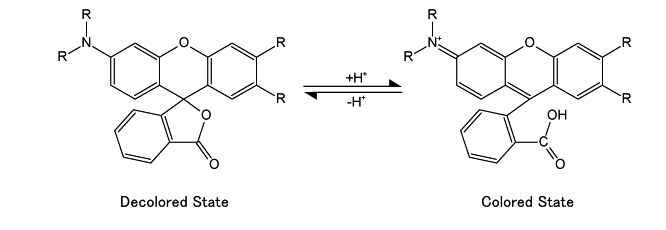

The mechanisms of ThermoRewrite are similar to those of traditional thermal paper, which is based on the reaction between a leuco dye and the developer. However, a specially designed developer is used. Reversible coloring and reversible erasing are achieved by controlling the amount of applied thermal energy and the cooling speed.

[Coloring]

When the mixture of leuco dye and developer is melted at around 170oC and

then cooled rapidly, the mixture changes from non-colored to a colored

state that is stable

at ordinary temperature.

[Erasing]

When the colored state mixture is heated again for a certain period of time at

120 -140oC and then cooled slowly, the developer creates stable crystalline

states,

and the mixture reverts back to the non-colored state.

Erasing and rewriting with rewritable printer

The printed image is erased by heating the media for a certain period of

time at the required erasing temperature and then cooling it slowly. An

erasing bar, erasing roll,

and thermal head are used to erase the printed image.

A new image is formed by heating the media for a very short time to the melting point (170 -180oC) and subsequently cooling it rapidly. A thermal head is used to supply energy.