B2 Size Compatible CTP

FREDIA Eco Wz

The popular FREDIA series has been renewed! Eco-friendly, space-saving, and easy to use. This fully automatic system fits perfectly into the customer's environment.

B2 Size Compatibility

Maximum output version size is 775mm. Compatible with B2 size printing machines.

Lower Processing Liquid Usage and Waste Liquid Volume

Continuing the use of coating and developing methods installed in FREDIA Eco W, the appropriate amount of processing liquid and waste liquid is used and maintained.

Built-in Punch

Up to 3 types of punches that meet the printing machine manufacturer's standards can be set (including customization). After printing, it can be loaded directly into the printing press, considerably eliminating bottlenecks in the plate-making process. In addition, since exposure processing is performed after punching, registration accuracy is greatly improved.

High Productivity

The output speed is approximately 30 plates per hour for the B2 size, yielding high productivity.

By adopting a "high-speed spinner motor" and "internal drum method," it has approximately twice the plate-making capacity compared to thermal CTP.

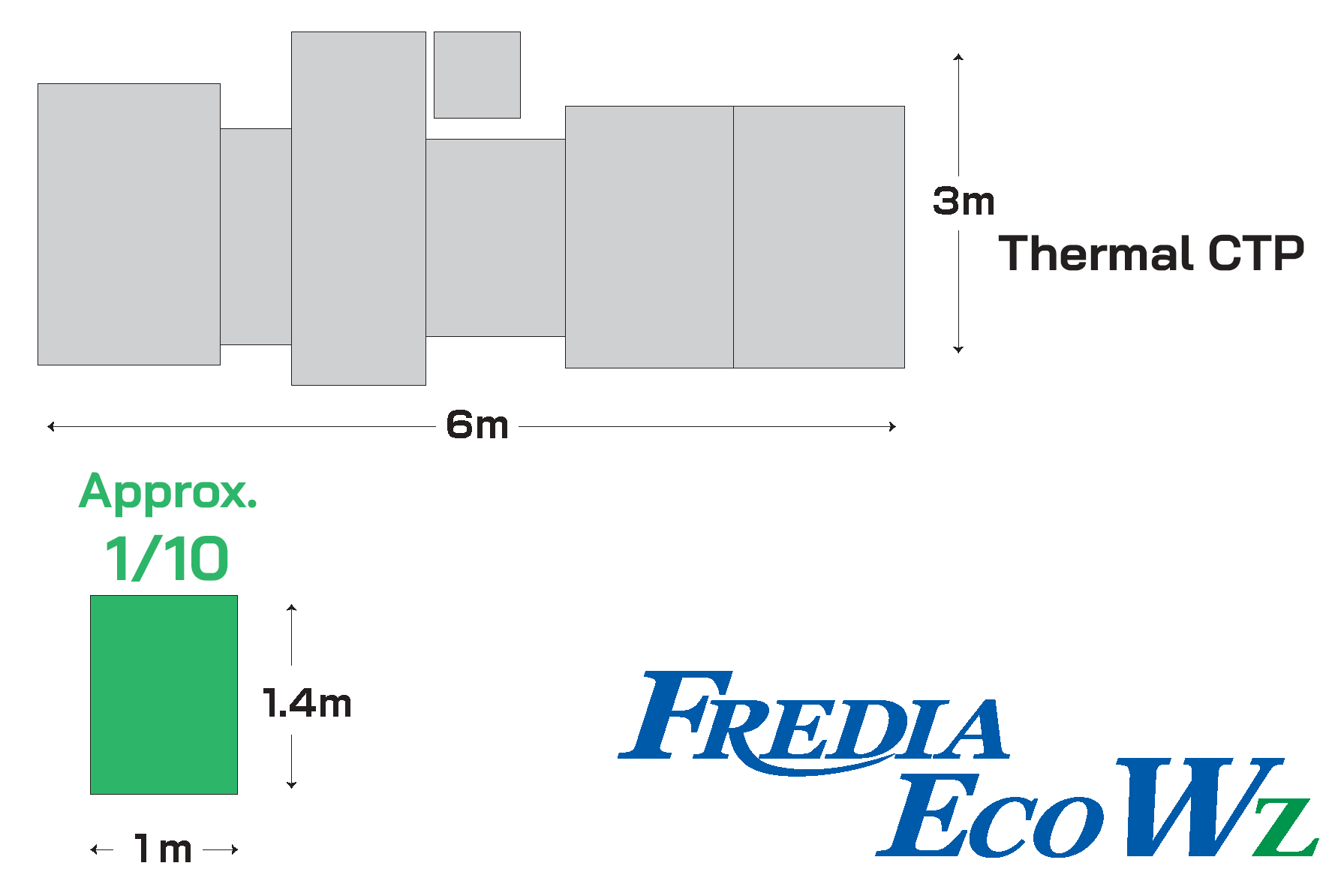

Space-Saving

The size of the FREDIA Eco Wz body is more space-saving compared to general thermal CTP, allowing for effective use of factory and office space.

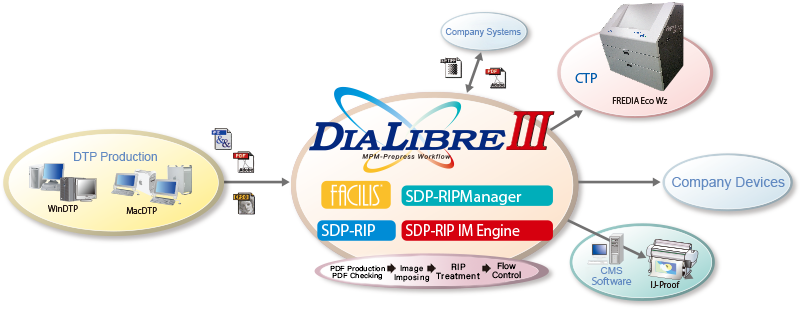

Native PDF and SDP-RIP Standard Support

In combination with SDP-RIP, multiple settings such as output line count, calibration, screening, and plate size can be made. Furthermore, everything from plate size switching to output is automatically processed without changing settings. *It is possible to receive and output 1-bit TIFF output from other companies' systems.

Workflow

Specifications

| Light Source | Red laser diode |

|---|---|

| Exposure Method | Internal drum system |

| Output Resolution | 1200dpi, 1800dpi, 2540dpi, 3000dpi |

| Output Speed | Approximately 30 sheets/hour (B2 Size) 2540dpi |

| Output Media | Fredia Plate (FPS-175) |

| Output Version Size | Minimum 305mm x 305mm Maximum 775mm x 680mm *The lower magazine can only be used with photosensitive materials with a width of 510mm or more. |

| Connection RIP | SDP-RIP |

| Capacitance | Single phase 200V~240V, 12A |

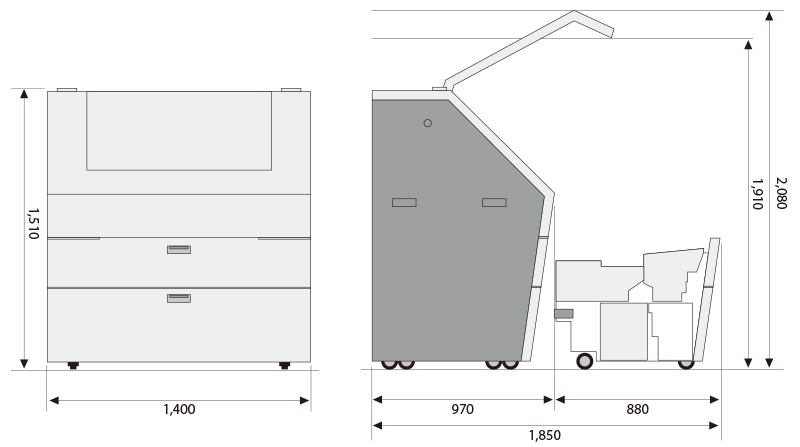

| External Dimensions (WxDxH) | 1,400×970×1,510mm |

| Environmental Condition | Temperature 18℃~25℃ Humidity 40~70% |

| Mass | 500kg (without processing liquid) |

| Built-in Punch | 425mm or 220mm Bach standard OP: Komori Punch |

Developing Section Specifications

| Tank Capacity | Developing: 1.2ℓ Stable: 5.8ℓ |

|---|---|

| Replenishment | Pressurized replenishment method |

| Processing Liquid Temperature Control | Temperature control unit: 150W developing , 300W stable Operating temperature: 33℃ developing , 18℃ stable |

| Waste Liquid System | Waste liquid overflow method: Tank capacity 30ℓ |

| Discharge Tray | 40 sheets (maximum) |

| Drying Section | Airflow method: 1,000W 30℃~50℃ |

Dimensions

Compatible Plates

FREDIA PLATE

Features

Highly Flexible

- Shortens delivery times for half-cut multicolor printing.

- Upgraded from the conventional product to improve water retention and printing stability.

- Easy to handle film plate, and the product is in a roll shape, so it requires minimal storage space.

Environmentally-Friendly

- Low energy plate making.

- Waste liquid can be treated the same as industrial waste.

- Compatible with liquid-saving development systems.

Specifications

| Base | Polyester |

|---|---|

| Plate Thickness | 0.20mm |

| Number of Sheets | 20,000 sheets with general offset ink (varies under printing conditions) |

Substances For Plate-Making

| Developer | Stabilizer |

|---|---|

| Stabilizer | SDP-FSTII |

Substances For Printing

| Non-Alcoholic Etching Liquid | SLM-OHIII |

|---|---|

| Dampening Solution | SLM-ODN, SLM-OD30N, SLM-OD50, SLM-OD・PSIII |

| Moisture-Control Additive | SML-OA1, SLM-OA2 |

| Correction Fluid / Correction 1 Pen | SLM-OE / SLM-OEII Pen |